Yilisha Hardware Co., Ltd was found in 2004. It is the subsidiary of Sunstrong Group which has over 6,000 employees worldwide and achieve over HKD 2 Billion annual revenue.

We have integrated the technical know-how, quality assurance system, project management system to provide the "one-stop service".

Yilisha has over 1,100 employees with 200 engineers in research & innovation team and has been recognized as one of the “key high-tech enterprises” by local government.

We are proud to work with Fortune Global 500 Enterprises such as Ericsson, TTI, Cisco, Philips, Hitachi, JVC, NEC, Stanley, Delta-q, Jabil, Ubtech, Smartdrive,KT,Eco Forest and others.

Our global sales team will always assist you .

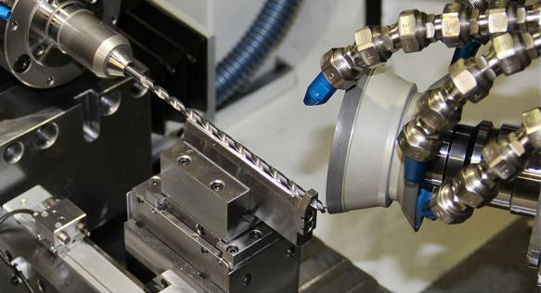

Contact usYilisha is a professional manufacturer in both precision metal and heavy-duty metal. We obtained international quality standard in different industries such as ISO9000 quality management system, ISO14001 environmental protection and safety, TS16949 automation product and ISO13485 medical device. We offer the service including stamping metal, sheet metal, CNC milling, CNC latches, Die-casting parts and after-treatment service.

We have>550 sets of advanced production equipment and >50 sets of high-end testing laboratory equipment to meet customer needs. >90% of our equipmentsare imported from Japan, Switzerland, Finland and US. We run in "LEAN" culture and follow the LEAN methodology to design the best logistics line, ergonomic work platform, low-energy low-cost environmental, etc.

Our Group includes 5 factories and 3 overseas offices with more than 6,000 employees worldwide and owns industrial park covering an area over 250,000 square meters.

Our factories are located in Dongguan&Shenzhen,Guangdong province and Kunshan,Jiangsu province.Overseas offices are located in Hong Kong, Japan and Singapore.